- Call us free 24/7 : +62-251-8434218

- info@vibrationmeter.id

Benstone vPod Pro Smart Vibration Meter

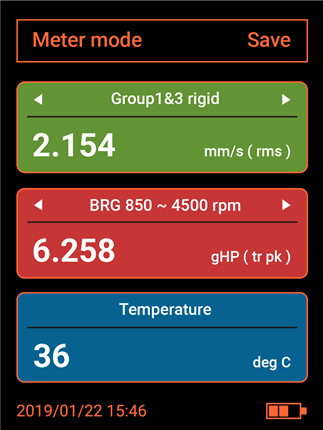

vPod Pro is our next generation smart vibration meter built around your need in machinery condition monitoring. With the innovatively designed sensor A52-IR, vPod Pro can measure vibration and temperature at the same time. The high-strength magnetic base secures the sensor for accurate transmission of high frequency signals from bearings or gears. After each measurement, vPod Pro displays 3 readings at the same time: vibration level, bearing condition and temperature. The severity status for each measurement is shown with easy to read background colors.

vPod Pro – Smart vibration meter/vibration analyzer/data collector

Download the vPod Pro Smart Vibration Meter brochure

Innovative design

vPod Pro is our next generation smart vibration meter built around your need in machinery condition monitoring.

With the innovatively designed sensor A52-IR, vPod Pro can measure vibration and temperature at the same time.

The high-strength magnetic base secures the sensor for accurate transmission of high frequency signals from bearings or gears.

After each measurement, vPod Pro displays 3 readings at the same time: vibration level, bearing condition and temperature.

The severity status for each measurement is shown with easy to read background colors.

Superior method for detecting damaged bearings

A damaged bearing will exhibit the periodic knocking signals in its vibration time waveform. vPod Pro implements the

field-proven “true-peak” detection, which can track early stage bearing damage. This detection method also proves to

be very effective for detect bearing damage on ultra-low speed machine.

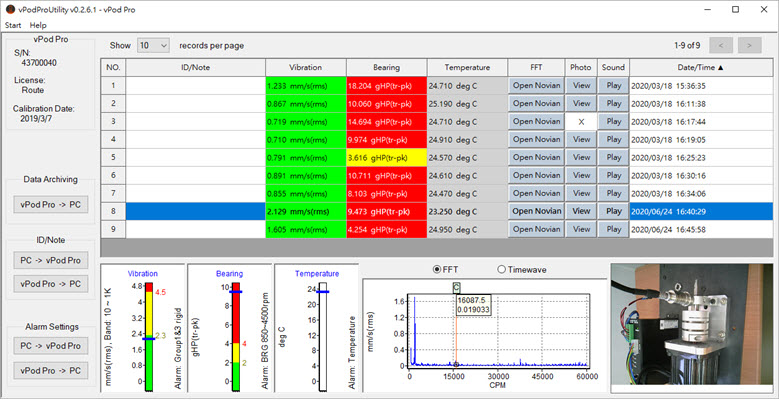

Powerful Utility and Novian sftware for data viewing and post analysis

vPod Pro allows you to listen to the raw signal via a Bluetooth headset, take and attach a picture to the stored data record.

With optional Spectrum version, vPod Pro can store the 10 kHz bandwidth raw signal to the built-in memory and let you

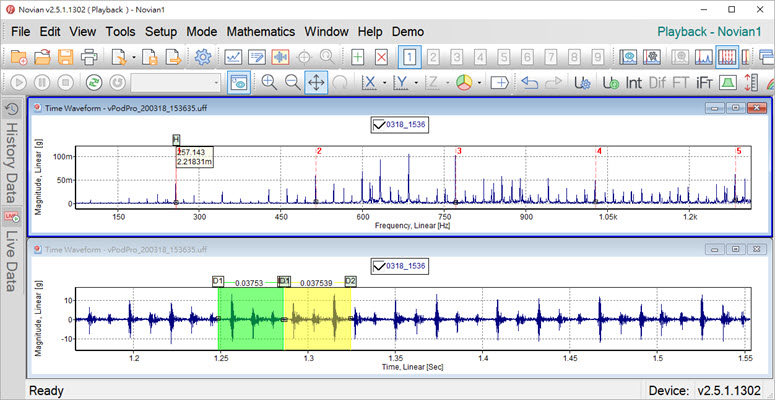

replay the sound files as many times as you wish. The users can also conduct post analysis on the stored raw data with

free Utility and Novian software to derive more detailed spectrum data.

Explore the measured data via the free Utility program.

Conduct post analysis of the measured data from the free software Novian.

Complete features in route mode

In the Route mode; basic vibration, bearing condition and temperature are measured, while in the background

the raw vibration signal is stored for further data analysis. When the measured data is imported into iSee computer

program, this raw signal is automatically converted into a time waveform, two sets of power spectrum, envelope

spectrum, and cepstrum to provide the most complete predictive maintenance monitoring parameters.

Specifications

- IP65 rated dustproof and waterproof case with anti-drop rubber sleeve

- Equipped with a 3.5″ color screen for intuitive and easy-to-understand operation interface

- Built-in 24G flash memory provides sufficient storage space

- Innovative sensor allows measurement of vibration values, bearing condition, and temperature at the same time

- Optional Spectrum Analysis Module and Route-based Vibration Data Collector Module

- A camera on the back allows you to add a photo taken on-site as a note when storing data

- Supports Bluetooth headset connection for listening to the vibration signal

- USB 2.0 and Wi-Fi transmission interface to transfer data to a PC.

The vPod Pro is powered by two off 18650 rechargeable batteries.

A vPod Pro kit comes with complete accessories.

Introduction videos:

Introduction to vPod Pro Smart Vibration Meter

Basic operations of the vPod Pro Smart Vibration Meter